Our Sustainability Pledge

Our designers and craftsmen focus on the natural characteristics and texture structure of cashmere,combine with ever-changing fashion concepts and customer needs, to deliver cashmere scarves made with the finest quality raw materials to every consumer.

Designing

When the cloth has been woven, the appearance is rough. There are many processes involved in transforming cashmere fabric into a luxurious finished items. We carry out strict quality control on the key processes that affect the style, feel and appearance quality of cashmere scarves during the finishing process to ensure that our cashmere items return to the most natural and super soft state. The suede feel of a cashmere scarf depends on the shrinking and raising process. The shrinking determines the fullness of the bottom fleece, and the raising determines the density and water wave pattern of the suede. Our craftsmen have fully considered the properties and structural characteristics of cashmere fabrics, and adjusted the process parameters reasonably to ensure the quality of all our cashmere products.

All our cashmere is ethically sourced from the native goat in Inner Mongolia. In the mill, we remove the coarse wool, extract the thinnest and longest cashmere fibers to ensure our products will be soft, delicate and stand the test of time.We use the carding machine to process these precious woolless cashmere into coarse tops, and then we spin these cashmere slivers into woolen cashmere yarn and worsted cashmere yarn according to the requirements of our technical director. Dyeing is also reasonably interspersed in the carding and spinning process according to the technological requirements.

Spinning

Weaving is like building a house, and it takes creativity, mathematical skills, technical understanding and dexterity to weave a good piece of fabric. Our weaving range is divided into plain weave, herringbone, broken thread, twill, crack and jacquard and so on. These patterns are woven delicately on our cashmere loom.

Weaving

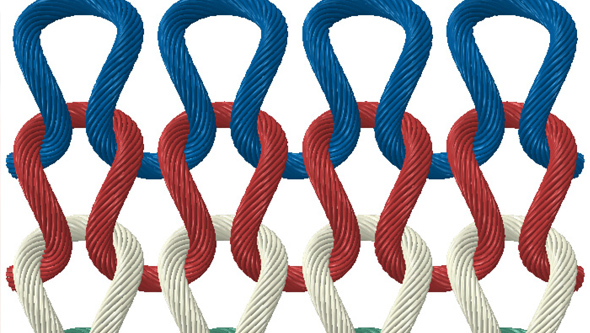

Innovative knitting machines provide us with complex knitting solutions and more creative space for craftsmen and designers. Colors, textures and designs are incorporated into the cashmere scarf,stitch by stitch,throughout the knitting process. Both sides of the scarf are visible when worn, so we added styles with different knitted structures and colors on both sides , making our cashmere scarves not only warm, soft, breathable, and skin-friendly, but also stylish and versatile.

Knitting

Finishing

Clear water and lush mountains are invaluable assets, which is the slogan of Inner Mongolia's sustainable development. As a responsible manufacturer, we always think twice about the impact on us and the planet.The acquisition of cashmere is a natural and recyclable process. Cashmere goats grow their fine warm undercoats before winter starts. However, as soon as the molting period of the goat (March), it starts shedding its precious hair. Winter in Inner Mongolia is pretty cold. The finest hair (cashmere) has been on goats’ body to survive in the freezing condition around. But as soon as summer arrives, it is hot. So the goats can’t bear the undercoat and it loses some naturally. The herders use specialized combs to comb off the rest gently. For Cashmere to be sustainable, it has to be pure. Cashmere scarves have a long life if taken proper care of. A 100% pure cashmere scarf has a life of over 25 years.